Introduction to Thermal Testing

(AKA Thermal Inspection, Thermography, Thermal Imaging, Thermal Wave Imaging and Infrared Testing)

Thermal NDT methods involve the measurement or mapping of surface temperatures as heat flows to, from and/or through an object. The simplest thermal measurements involve making point measurements with a thermocouple. This type of measurement might be useful in locating hot spots, such as a bearing that is wearing out and starting to heat up due to an increase in friction.

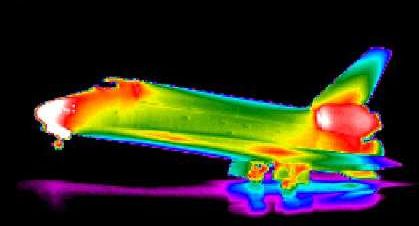

In its more advanced form, the use of thermal imaging systems allow thermal information to be very rapidly collected over a wide area and in a non-contact mode. Thermal imaging systems are instruments that create pictures of heat flow rather than of light. Thermal imaging is a fast, cost effective way to perform detailed thermal analysis. The image above is a heat map of the space shuttle as it lands.

Thermal measurement methods have a wide range of uses. They are used by the police and military for night vision, surveillance, and navigation aid; by firemen and emergency rescue personnel for fire assessment, and for search and rescue; by the medical profession as a diagnostic tool; and by industry for energy audits, preventative maintenance, processes control and nondestructive testing. The basic premise of thermographic NDT is that the flow of heat from the surface of a solid is affected by internal flaws such as disbonds, voids or inclusions. The use of thermal imaging systems for industrial NDT applications will be the focus of this material.