Thermal Testing Equipment: Detectors

Thermal energy detection and measurement equipment comes in a large variety of forms and levels of sophistication. One way to categorize the equipment and materials is to separate thermal detectors from quantum (photon) detectors. The basic distinction between the two is that thermal detectors depend on a two-step process. The absorption of thermal energy in these detectors raises the temperature of the device, which in turn changes some temperature-dependent parameter, such as electrical conductivity. Quantum devices detect photons from infrared radiation. Quantum detectors are much more sensitive but require cooling to operate properly.

Thermal Detectors

Thermal detectors include heat sensitive coatings, thermoelectric devices and pryoelectric devices. Heat sensitive coatings range from simple wax-based substances that are blended to melt at certain temperatures to specially formulated paint and greases that change color as temperature changes. Heat sensitive coatings are relatively inexpensive but do not provide good quantitative data.

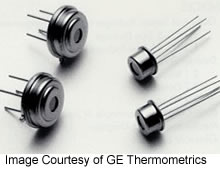

Thermoelectric devices include thermocouples, thermopiles (shown right), thermistors and bolometers. These devices produce an electrical response based on a change in temperature of the sensor. They are often used for point or localized measurement in a contact or near contact mode. However, thermal sensors can be miniaturized. For example, mirobolometers are the active elements in some high-tech portable imaging systems, such as those used by fire departments. Benefits of thermal detectors are that the element does not need to be cooled and they are comparatively low in price. Thermal detectors are used to measure the temperature in everything from home appliances to fire and intruder detection systems to industrial furnaces to rockets.

Thermoelectric devices include thermocouples, thermopiles (shown right), thermistors and bolometers. These devices produce an electrical response based on a change in temperature of the sensor. They are often used for point or localized measurement in a contact or near contact mode. However, thermal sensors can be miniaturized. For example, mirobolometers are the active elements in some high-tech portable imaging systems, such as those used by fire departments. Benefits of thermal detectors are that the element does not need to be cooled and they are comparatively low in price. Thermal detectors are used to measure the temperature in everything from home appliances to fire and intruder detection systems to industrial furnaces to rockets.

Quantum (Photon) Detectors

Unlike thermal detectors, quantum detectors do not rely on the conversion of incoming radiation to heat, but convert incoming photons directly into an electrical signal. When photons in a particular range of wavelengths are absorbed by the detector, they create free electron-hole pairs, which can be detected as electrical current. The signal output of a quantum detector is very small and is overshadowed by noise generated internally to the device at room temperatures. Since this noise within a semiconductor is partly proportional to temperature, quantum detectors are operated at cryogenic temperatures [i. e. down to 77 K (liquid nitrogen) or 4 K (liquid helium)] to minimize noise. This cooling requirement is a significant disadvantage in the use of quantum detectors. However, their superior electronic performance still makes them the detector of choice for the bulk of thermal imaging applications. Some systems can detect temperature differences as small as 0.07°C.

Unlike thermal detectors, quantum detectors do not rely on the conversion of incoming radiation to heat, but convert incoming photons directly into an electrical signal. When photons in a particular range of wavelengths are absorbed by the detector, they create free electron-hole pairs, which can be detected as electrical current. The signal output of a quantum detector is very small and is overshadowed by noise generated internally to the device at room temperatures. Since this noise within a semiconductor is partly proportional to temperature, quantum detectors are operated at cryogenic temperatures [i. e. down to 77 K (liquid nitrogen) or 4 K (liquid helium)] to minimize noise. This cooling requirement is a significant disadvantage in the use of quantum detectors. However, their superior electronic performance still makes them the detector of choice for the bulk of thermal imaging applications. Some systems can detect temperature differences as small as 0.07°C.

Quantum detectors can be further subdivided into photoconductive and photovoltaic devices. The function of photoconductive detectors are based on the photogeneration of charge carriers (electrons, holes or electron-hole pairs). These charge carriers increase the conductivity of the device material. Possible materials used for photoconductive detectors include indium antimonide (InSb), quantum well infrared photodetector (QWIP), mercury cadmium telluride (mercad, MCT), lead sulfide (PbS), and lead selenide (PbSe).

Photovoltaic devices require an internal potential barrier with a built-in electric field in order to separate photo-generated electron-hole pairs. Such potential barriers can be created by the use of p-n junctions or Schottky barriers. Examples of photovoltaic infrared detector types are indium antimonide (InSb), mercury cadmium telluride (MCT), platinum silicide (PtSi), and silicon Schottky barriers.

Detector Cooling

There are several different ways of cooling the detector to the required temperature. In the early days of thermal imaging, liquid nitrogen was poured into imagers to cool the detector. Although satisfactory, the logistical and safety implications led to the development of other cooling methods. High pressure gas can be used to cool a detector to the required temperatures. The gas is allowed to rapidly expand in the cooling systems and this expansion results in the significant reduction in the temperature of a gas. Mechanical cooling systems are the standard for portable imaging systems. These have the logistical advantage of freeing the detection system from the requirements of carrying high pressure gases or liquid nitrogen.