Image Resolution

System resolution depends on a number of factors that include X-ray source focal-spot size, magnification, and imaging system performance. Imaging system performance depends mainly on the quality of the image intensifier, camera, frame grabber board, monitor or other components used. In general, RTR systems are not able to resolve as small of a defect as can be resolved using film radiography. This is primarily due to limitation of the image intensifier, which will be discussed in more detail later. However, with the use of image processing program the performance of RTR systems can be improved. Further, since magnification is easily accomplished with RTR systems equipped with sample positioning systems resolution can be significantly improved especially when minifocus or microfocus x-ray tubes are used. Table 1 provides a comparison the performance between film radiography and various RTR systems.

| Film Radiograph | Conventional RTR | RTR with Image Processing | Microfocus RTR with Image Processing | |

| Resolution | 0.1 to 0.06 mm (0.004 to 0.002 inch) | 0.5 to 0.25 mm (0.02 to 0.01 inch) | 0.5 to 0.25 mm (0.02 to 0.01 inch) | Up to 0.05 mm (0.002 inch) |

| Contrast Sensitivity | 1 to 2% | 3 to 4% | 0.5 to 1% | 0.5 to 1% |

| Speed | 5 to 15 min/image | Real time | 1 to 30 sec/image | 1 to 30 sec/image |

Table 1. Performance comparison between film and various RTR system configurations.

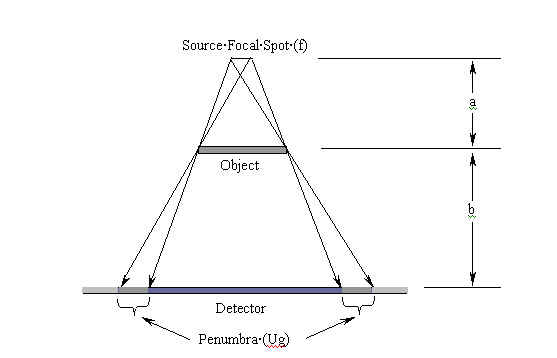

When magnification is used in an RTR system, the geometric unsharpness of the inspection setup needs to be taken into consideration. The size of the X-ray tube focal-spot and the magnification factors, namely the source-to-specimen and specimen-to-detector distances, are used to calculate the geometric unsharpness of the inspection setup. Geometric unsharpness (Ug) is determined as follows:

f = X-ray generator focal-spot size.

a = distance from x-ray source to front surface of material/object

b = distance from the material/object to the detector

To minimize the penumbra, the test specimen is usually placed as close as possible to the detector and the source is placed some distance from the sample. A greater distance between the source and the object will reduce geometric unsharpness. However, the intensity of the source decreases as the distance increases. Therefore, the source should be placed only as far away as necessary to control the penumbra. If the test object is placed in direct contact with the detector (like is often done in film radiograph) the following formula can be used that takes into account the material thickness instead of the object-to-detector distance. This formula is:

f = X-ray generator focal spot size

t = the thickness of the material

d = distance from x-ray source to front surface of material/object

The allowable amount of unsharpness is controlled by specification being followed. In general, the allowable amount is 1/100 of the material thickness up to a maximum of 0.040 inch.