Chipless RFID

Radio frequency identification (RFID) systems consist of a few main components, namely a reader, a reader antenna, and a tag. The tag is what stores identification or sensing information that can be accessed by interrogating the tag with an electromagnetic wave. Chipless RFID is a subset of the RFID field where the tags have no electronics and no power source, making chipless tags completely wireless and passive. Instead, they consist of a collection of patch antennas, microstrips lines, and planar resonators. When the tag is interrogated with an electromagnetic wave, they scatter back a response. This response can be viewed in the time-domain or frequency-domain and by examining changes in the response either identification or sensing can be performed.

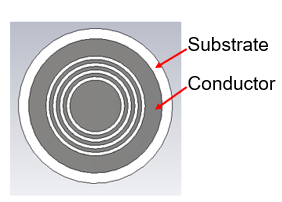

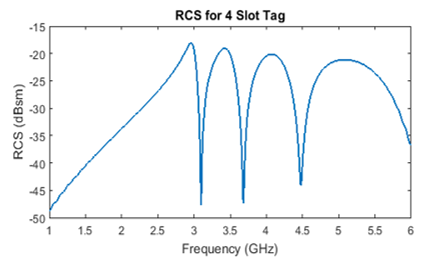

An example of a chipless RFID tag and its radar cross-section (RCS) response in the frequency-domain are shown below. For this tag, each of the four circular slot cutouts is a slot resonator that produces one resonance (also referred to as a notch) in the tag’s response. By removing a slot resonator (i.e., filling it with conductor), a notch will be removed from the response.

Example of a chipless RFID tag and its response in the frequency domain.

The presence and absence of notches can be used to assign a binary code to the response. This binary code can serve as an ID that is associated with the tag. When the response is changed by changing the structure of the tag, a new ID is created. For example, if the inner most slot resonator of the tag above was removed, which corresponds to the last notch in the response, and a coding method where notches are 1s was used, then the code would change from [1111] to [1110].

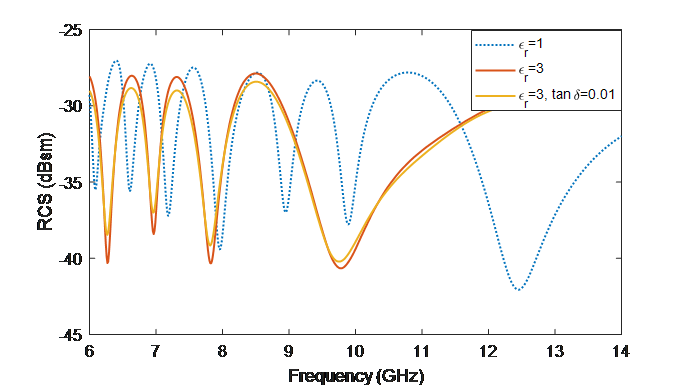

Chipless RFID tags can also be used for sensing when the response changes as a function of the environment that the tag is in. One sensing application of interest for chipless RFID is embedded microwave materials characterization. In this application, the tag is embedded into a dielectric material and its response changes as a function of the material it is in. An example of the tag response when it is embedded in a material with a relative permittivity of 3 and varying loss tangent as compared to when the tag is in free space (r=1) is shown below. As can be seen, as the permittivity of the embedding material increases, the response of the tag shifts down in frequency. Additionally, as the loss tangent increases, the resonant depth and quality factor of the resonances decreases. These changes in the response can then be used to determine what the dielectric properties of the embedding material are.

Example of chipless RFID tag responses when the tag is embedded into a material.

Other sensing applications of interest for chipless RFID include the monitoring of temperature, humidity, strain, rotation, and pressure and the detection of cracks in metal structures and delaminations in multilayer dielectric structures. Tags that can sense multiple parameters have also been explored.

The table below outlines the advantages and challenges associated with chipless RFID. Overall, chipless RFID is still a relatively new technology and as such there are a variety of challenges that need to be overcome to make it practical for use outside of a laboratory setting.

| Advantages | Challenges |

|

Wireless |

Low information density |

|

Passive |

Low read ranges |

|

Could be flexible and fully printable due to the lack of electronics |

Extreme tag/reader misalignment sensitivity |

|

Non-contact reading |

Difficult to differentiate multiple tags in the same vicinity |

|

Capable of being used in extreme environments |