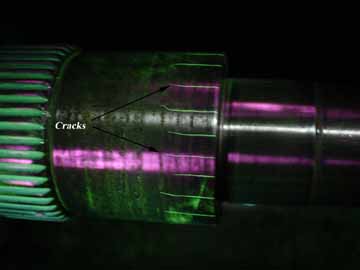

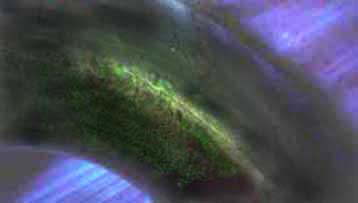

Fluorescent Wet Magnetic Particle Indications

The indications produced using the wet magnetic particles are more sharp than dry particle indications formed on similar defects. When fluorescent particles are used, the visibility of the indications is greatly improved because the eye is drawn to the "glowing" regions in the dark setting. Below are a few examples of fluorescent wet magnetic particle indications.

.jpg)

.jpg)