Stationary Magnetizing Equipment

Stationary magnetic particle inspection equipment is designed for use in laboratory or production environment. The most common stationary system is the wet horizontal (bench) unit. Wet horizontal units are designed to allow for batch inspections of a variety of components. The units have head and tail stocks (similar to a lathe) with electrical contact that the part can be clamped between. A circular magnetic field is produced with direct magnetization. The tail stock can be moved and locked into place to accommodate parts of various lengths. To assist the operator in clamping the parts, the contact on the headstock can be moved pneumatically via a foot switch.

Stationary magnetic particle inspection equipment is designed for use in laboratory or production environment. The most common stationary system is the wet horizontal (bench) unit. Wet horizontal units are designed to allow for batch inspections of a variety of components. The units have head and tail stocks (similar to a lathe) with electrical contact that the part can be clamped between. A circular magnetic field is produced with direct magnetization. The tail stock can be moved and locked into place to accommodate parts of various lengths. To assist the operator in clamping the parts, the contact on the headstock can be moved pneumatically via a foot switch.

Most units also have a movable coil that can be moved into place so the indirect magnetization can be used to produce a longitudinal magnetic field. Most coils have five turns and can be obtained in a variety of sizes. The wet magnetic particle solution is collected and held in a tank. A pump and hose system is used to apply the particle solution to the components being inspected. Either the visible or fluorescent particles can be used. Some of the systems offer a variety of options in electrical current used for magnetizing the component. The operator has the option to use AC, half wave DC, or full wave DC. In some units, a demagnetization feature is built in, which uses the coil and decaying AC.

To inspect a part using a head-shot, the part is clamped between two electrical contact pads. The magnetic solution, called a bath, is then flowed over the surface of the part. The bath is then interrupted and a magnetizing current is applied to the part for a short duration, typically 0.5 to 1.5 seconds. (Precautions should be taken to prevent burning or overheating of the part.) A circular field flowing around the circumference of the part is created. Leakage fields from defects then attract the particles to form indications.

To inspect a part using a head-shot, the part is clamped between two electrical contact pads. The magnetic solution, called a bath, is then flowed over the surface of the part. The bath is then interrupted and a magnetizing current is applied to the part for a short duration, typically 0.5 to 1.5 seconds. (Precautions should be taken to prevent burning or overheating of the part.) A circular field flowing around the circumference of the part is created. Leakage fields from defects then attract the particles to form indications.

When the coil is used to establish a longitudinal magnetic field within the part, the part is placed on the inside surface of the coil. Just as done with a head shot, the bath is then flowed over the surface of the part. A magnetizing current is applied to the part for a short duration, typically 0.5 to 1.5 seconds, just after coverage with the bath is interrupted. (Precautions should be taken to prevent burning or overheating of the part.) Leakage fields from defects attract the particles to form visible indications.

When the coil is used to establish a longitudinal magnetic field within the part, the part is placed on the inside surface of the coil. Just as done with a head shot, the bath is then flowed over the surface of the part. A magnetizing current is applied to the part for a short duration, typically 0.5 to 1.5 seconds, just after coverage with the bath is interrupted. (Precautions should be taken to prevent burning or overheating of the part.) Leakage fields from defects attract the particles to form visible indications.

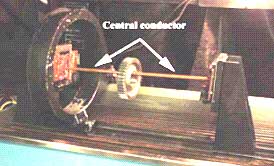

The wet horizontal unit can also be used to establish a circular magnetic field using a central conductor. This type of a setup is used to inspect parts that have an open center, such as gears, tubes, and other ring-shaped objects. A central conductor is an electrically conductive bar that is usually made of copper or aluminum. The bar is inserted through the opening and the bar is then clamped between the contact pads. When current is passed through the central conductor, a circular magnetic field flows around the bar and enters into the part or parts being inspected.

The wet horizontal unit can also be used to establish a circular magnetic field using a central conductor. This type of a setup is used to inspect parts that have an open center, such as gears, tubes, and other ring-shaped objects. A central conductor is an electrically conductive bar that is usually made of copper or aluminum. The bar is inserted through the opening and the bar is then clamped between the contact pads. When current is passed through the central conductor, a circular magnetic field flows around the bar and enters into the part or parts being inspected.