Swept Frequency

Swept frequency eddy current techniques involve collecting eddy current data at a wide range of frequencies. This usually involves the use of a specialized piece of equipment such as an impedance analyzer, which can be configured to automatically make measurements over a range of frequencies. The swept-frequency technique can be implemented with commercial equipment but it is a difficult and time-consuming measurement. The advantage of a swept frequency measurement is that depth information can be obtained since eddy current depth of penetration varies as a function of frequency.

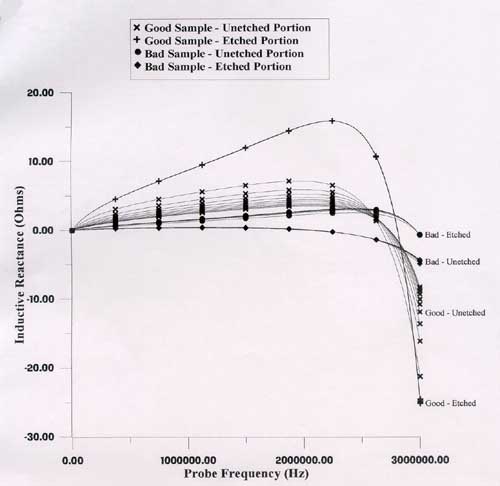

Swept frequency measurements are useful in applications such as measuring the thickness of conductive coatings on conductive base metal, differentiating between flaws in surface coatings and flaws in the base metal and differentiating between flaws in various layers of built-up structure. An example application would be the lap splice of a commercial aircraft. Swept frequency measurements would make it possible to tell if cracking was occurring on the outer skin, the inner skin or a double layer. Below is an example of the type of data that can be obtained from swept-frequency measurements.

It can be seen that in the etched condition, the material labeled "good" exhibits a much different signal response than the material labeled "bad." It can also be seen that a frequency of around 2.2 MHz provides the largest separation in the curves. Therefore, this frequency should be used if a single frequency is used to sort the parts made from the two metals.