Pulsed Eddy Current Inspection

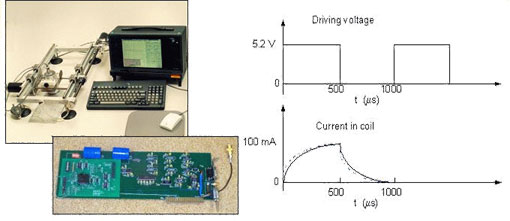

Conventional eddy current inspection techniques use sinusoidal alternating electrical current of a particular frequency to excite the probe. The pulsed eddy current technique uses a step function voltage to excite the probe. The advantage of using a step function voltage is that it contains a continuum of frequencies. As a result, the electromagnetic response to several different frequencies can be measured with just a single step. Since the depth of penetration is dependent on the frequency of excitation, information from a range of depths can be obtained all at once. If measurements are made in the time domain (that is by looking at signal strength as a function of time), indications produced by flaws or other features near the inspection coil will be seen first and more distant features will be seen later in time.

To improve the strength and ease interpretation of the signal, a reference signal is usually collected, to which all other signals are compared (just like nulling the probe in conventional eddy current inspection). Flaws, conductivity, and dimensional changes produce a change in the signal and a difference between the reference signal and the measurement signal that is displayed. The distance of the flaw and other features relative to the probe will cause the signal to shift in time. Therefore, time gating techniques (like in ultrasonic inspection) can be used to gain information about the depth of a feature of interest.