Recommended Education, Training, and Certification for NDE Engineers

Unlike some other engineering disciplines, there are no formally established requirements for education, training, certification, etc. for NDE engineers. Most NDE engineers were formally educated in other disciplines and then stumbled into the NDE field during their careers and obtained additional education, training, and experience on the job to enable them to fulfill their job responsibilities. Additionally, those job responsibilities for an NDE engineer may vary widely from one place of employment to another, and even across different physical or organization locations within a single place of employment. Examples of responsibilities that might be performed by an NDE engineer include:

-

Management of the NDE technician/inspector workforce to include assigning inspection duties, ensuring training/certification requirements are met and maintained, and developing and proctoring certification testing

-

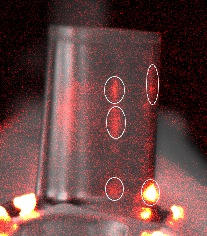

Analysis and review of NDE inspection results and reporting of inspection findings

NDE inspection results with possible indications circled, as might be reviewed by an NDE engineer

Image credit: S. Holland -

Selection, development, and documentation of NDE methods for specific inspection applications

-

Research and development of new NDE methods, or modifications of existing NDE methods for new applications

-

Providing insight and/or oversight of NDE organizations at contractor/subcontractor locations that are responsible for NDE of incoming products (e.g. raw materials, component and subcomponent assemblies, and finished hardware) or for periodic inspections of structures in use (e.g. fleets of ships, airplanes, etc.)

Given the diversity in job responsibilities and applications of NDE, it is difficult to specify a one size fits all set of requirements for an NDE engineer. However, the following are some general recommended education, training, and certification opportunities that would enable one to be successful as an NDE engineer in many industries.

Education: Generally, a BS degree in science or engineering from an accredited institution is considered as a minimum education requirement to qualify for an engineering position. However, in some cases, graduate education or degrees may be desired or necessary. Given the variety of applications of NDE, there is not one specific science or engineering discipline that is preferential for an NDE engineer. However, as most NDE techniques involve the interaction of some type of energy (e.g. electrical, thermal, mechanical, etc.) with the material being inspected, the coursework for this degree should include physics, chemistry, and materials science, which are prerequisites for many engineering discipline degrees. Additionally, NDE techniques involve the use of sensors, electronics, data acquisition and analysis, and thus coursework in electronics and computer science/engineering is extremely valuable. Further, as the applications of NDE most often involve the inspection of structural materials or systems, coursework in mechanical or civil engineering to include strength of materials, statics and dynamics, and structural design are necessary to effectively perform the duties of an NDE engineer. A good foundation in probability and statistics is also important to understand the statistical nature of NDE and the associated requirements for probability of detection. An introductory survey course on NDE methods is also highly recommended, but may not be available at many universities, so this knowledge may need to be acquired through additional training.

Training: As noted above, there may be limited formal education opportunities at most universities for either an overview of, or for specific NDE methods. Thus, it may be necessary that this knowledge is obtained by training, either through employer provided on-the-job training or through the various commercial NDE training companies. As an NDE engineer will typically have to evaluate and select from a variety of NDE methods for a particular inspection application, at a minimum they should have training that provides a general overview of the most commonly used NDE methods (e.g. visual, dye penetrant, magnetic particle, radiography, ultrasonics, and eddy current). Additional training should also be obtained for the specific methods that are in-use at the work location of the NDE engineer. Depending on the requirements for the specific applications of NDE, it may also be necessary to have formal training on probability of detection for NDE methods. Additional training to address any educational shortfalls from those listed above should also be considered.

Certification: Certification entails a formal recognition of both training, experience, and successful passing of proficiency testing for a specific NDE method or methods. Depending on the requirements at the particular work location, such certification may be required before an NDE engineer can participate in performing an inspection, analyzing inspection results, or developing and proctoring certification testing for technician/inspection personnel. However, in many situations, such certification is not required and is difficult to maintain as the NDE engineer may not regularly participate in the inspection process and thus have difficulty acquiring the required proficiency hours. A particular example is for NDE engineers involved in research and development, where they work with a variety of techniques, but do not regularly use the same techniques or perform field inspections of hardware.